Product

current location :Home > Product > Rotogravure Printing Machines

Model Series of Computer High-speed Rotogravure Presses

- Features

- Use

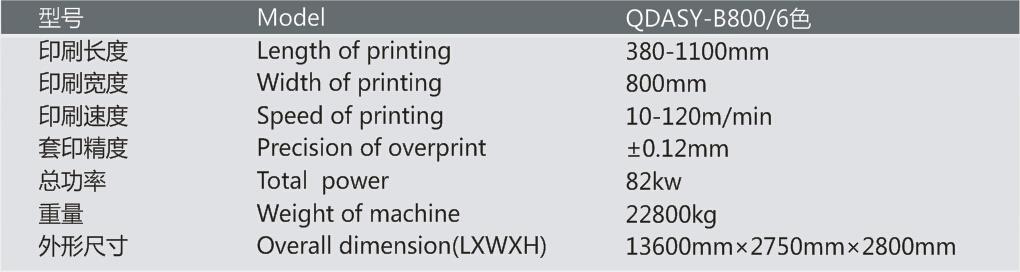

- Technical parameter

- Download

1. The whole set is in permutation and combination style, possible to add and reduce color class and add

on reverse printing mechanism as required by customers.

2. Frequency conversing synchronic timing is adopted for both main machine drawing and reeling.

3. Pneumatic backpressure moving erasing knife, non-shaft pneumatic conic node printing plate loading,

prompt and convenient printing plate changing.

4. Adopting control method of auto permanent tension and magnetic powder brake for unreeling.

5. Adopting pneumatic elements for control of all printing pressure roller, drawing pressure roller and open

& close of oven.

6. Sealed type lengthened oven, fast drying with less energy consuming, and auto constant temperature

control system.

7. Printing ink circulating system, inflatable type shaft draw in and draw out.

8. High-accuracy gear transmission box.

9. Reeling and unreeling reel by tumbling dual-station mechanism, realizing auto material change without

machine halt.

10. Adopting aluminum alloy guide roll after anode oxidation processing and in balance.

11. Full automatic computer registering devices and computer still examining graphics.

12. Diesel oil air-stove system is available for stove heating.

on reverse printing mechanism as required by customers.

2. Frequency conversing synchronic timing is adopted for both main machine drawing and reeling.

3. Pneumatic backpressure moving erasing knife, non-shaft pneumatic conic node printing plate loading,

prompt and convenient printing plate changing.

4. Adopting control method of auto permanent tension and magnetic powder brake for unreeling.

5. Adopting pneumatic elements for control of all printing pressure roller, drawing pressure roller and open

& close of oven.

6. Sealed type lengthened oven, fast drying with less energy consuming, and auto constant temperature

control system.

7. Printing ink circulating system, inflatable type shaft draw in and draw out.

8. High-accuracy gear transmission box.

9. Reeling and unreeling reel by tumbling dual-station mechanism, realizing auto material change without

machine halt.

10. Adopting aluminum alloy guide roll after anode oxidation processing and in balance.

11. Full automatic computer registering devices and computer still examining graphics.

12. Diesel oil air-stove system is available for stove heating.

Machines in this series are applicable for continuous multi-color printing on rolling materials

in good printing performance such as cellophane, BOPP, PET, PVC, PE, aluminum foil, and paper,

broadly applied for all types of super-quality printed matters.

in good printing performance such as cellophane, BOPP, PET, PVC, PE, aluminum foil, and paper,

broadly applied for all types of super-quality printed matters.

Online Service01

Online Service01